There are many reasons why models take a long time to run. This post explains the common causes for slow running models and possible solutions.

1. Input geometry files are too large

Before building the octree mesh, FLAC3D will first import the model geometries. Excessively large geometry files could take several hours to import. Consider the following actions to reduce geometry file size:

a) Check units of measurement – Using the wrong units of measurement can upscale geometries by many orders of magnitude. If using RhinoCAD, units of measurement are displayed at the bottom of the window. Right-click the unit of measurement and select ‘Unit Settings’ to change units. To verify the size of mesh components, click the ‘Analyze’ tab and select ‘Distance’.

b) Remove duplicate shapes – In Rhino, type ‘_ExtractDuplicateMeshFaces’ to remove duplicate shapes.

c) Reduce mesh resolution – Use the ‘_Reducemesh’ command to reduce the number of polygons comprising a shape.

2. Model size is unrealistic or exceeds PC specifications

Model size is largely controlled by the number of zones generated. Models with large numbers of zones are more geometrically accurate but also take longer to run. Consider the following actions to reduce model size:

a) Adjust global octree meshing parameter – Firstly, select a suitable target number of zones. StopeX works best when the target number of zones does not exceed 2.6 million. It may be necessary to further reduce the target number of zones to meet your PC specifications. To help StopeX achieve this target, consider increasing the far field zone size; increasing the initial zone multiplier and reducing the model boundary offset.

b) Use the Area of Interest function – The AOI function is used to preserve geometrical accuracy for mesh inside the AOI, meaning mesh outside the AOI can be coarsened to reduce model runtime.

c) Adjust model component meshing – Reducing the zone sizes for stope, development, topography and historical model components will reduce their geometrical accuracy but reduce model runtime. Consider reducing zone densification distance; reducing relative geometry accuracy; increasing initial zone size and increasing minimum permissible zone size. Generally speaking, historical zone size can be relatively coarse.

d) Trim/crop model components using CAD software – For example, using the fault functionality can greatly increase the number of zones generated. The shapes that control fault thickness and meshing need not extend to the model offset. Cropping these shapes to within the AOI will reduce the number of generated zones.

e) Reduce number of model steps – Models with fewer steps will take less time to run. Users should aim to sequence their model using the least number of steps but use enough steps to accurately model the mining sequence.

3. The model cannot reach equilibrium

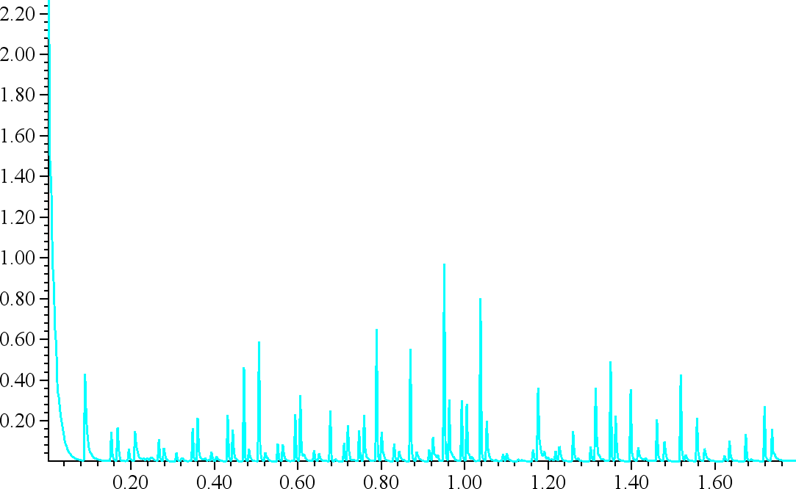

StopeX models will continue to run until mechanical forces are sufficiently balanced. The figure below shows the typical history chart for an equilibrated model – note the series of sharp peaks:

There are many reasons why a model will fail to equilibrate:

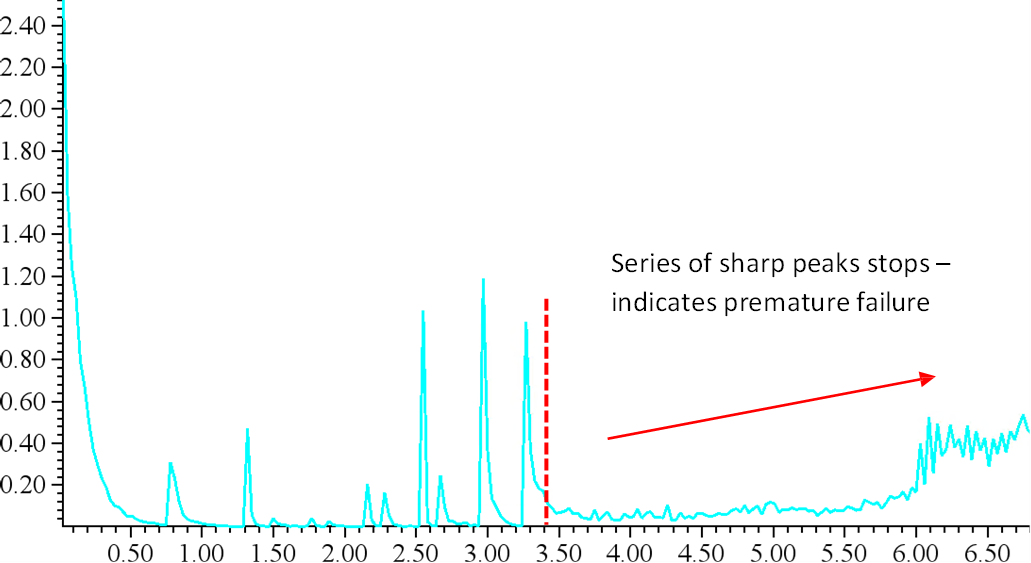

- a) Model steps contain too many stopes – The figure below shows a typical history chart for a model generating a void larger than is permitted by geotechnical constraints:

Placing adjacent stopes in the same step should therefore be avoided. Additional model steps may be required to prevent this. Models should be sequenced using the least number of steps to reduce runtime. However, enough steps should be used to accurately model the mining sequence.

b) Backfill component is invalid – The backfill component must include all voids that have been backfilled. Ensure the backfill component includes all backfilled stopes, as well as any backfilled historical voids.

c) Model components are above ground surface elevation – Any geometries above ground surface elevation will be in tension, meaning the model will not equilibrate. Using CAD software, ensure the topography and other shape files are at the correct ground surface elevation.