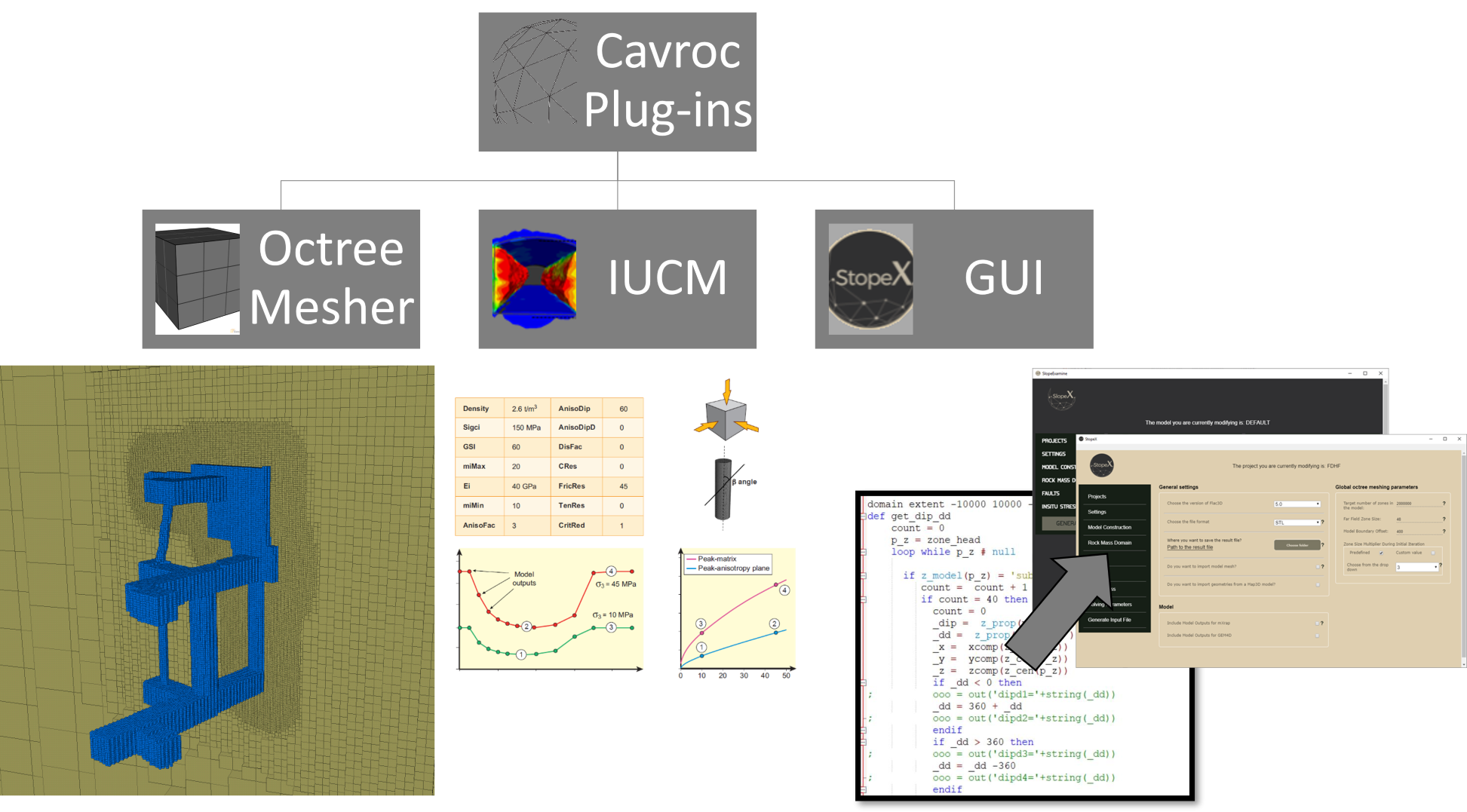

There are three main parts to StopeX and SlopeX, the “octree mesher” , “Improved Unified Constitutive Model” and “StopeX/SlopeX GUIs”.

What these are is below:

Octree Mesher: This gets around having to build a mesh. The octree meshes get around the difficulties of having to check for geometry intersections/overlaps which are usually associated with meshes. Building a mesh IS VERY ANNOYING AND TIME-CONSUMING. IMAGINE INTERSECTIONS IN MAP3D, x1000) StopeX/SlopeX doesn’t require “you” to build any geometry, just import the design files or CMS’ and it’ll do the rest. The mining sequence is attached to the input geometry files meaning it is effortless to import modified stopes/development.

Improved Unified Constitutive Model: This is how FLAC3D is instructed to make things behave. This uses many complex nonlinear behaviors to match the real-world response. Is capable of including rock fabric (anisotropy) or some plane of weakness (e.g. bedding). This is a “non-proprietary” (i.e. what it does under the hood is freely available) method and it does the same (if not better) to what Itasca or Beck Engineering methods do. The difference with IUCM is that it isn’t a secret what it does.

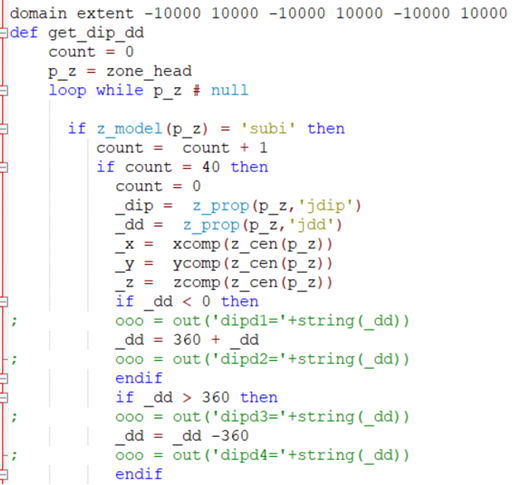

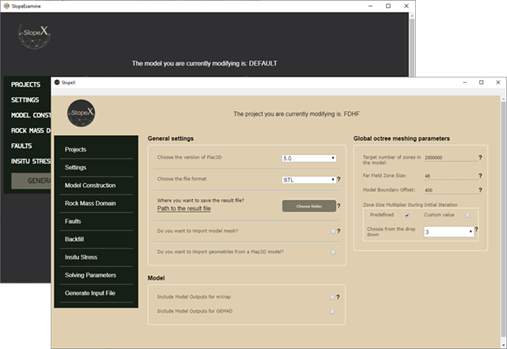

StopeX: this is the main magic. It turns “this”

Into “THIS”

Basically, it removes the tedious process of manually writing code to get FLAC3D do anything. This saves you about 5-10 years.

The “Short” version of what StopeX + IUCM is, is “Abaqus with the complexity of Map3D”. It’ll give you the same (if not better) model response as Abaqus, but doesn’t require the 10 years of specialist knowledge. You import the mine geometry and mining sequence, then press run and it’ll do the rest.

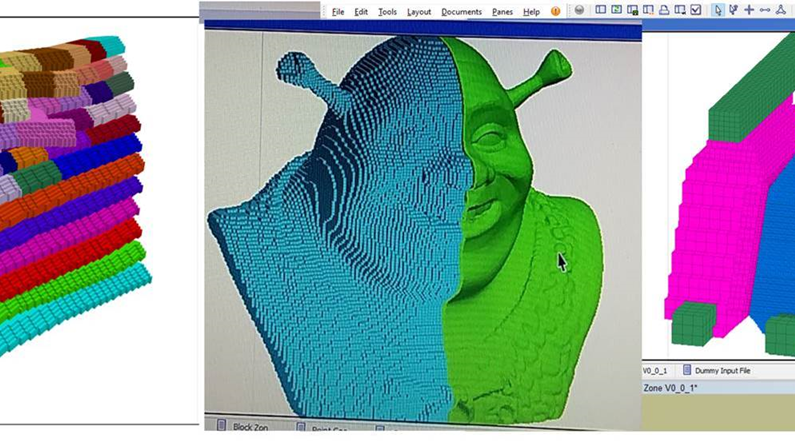

Octree meshes for reference are like so. The accuracy of what and where in the model is really up to you. The far-right picture shows an example of changing the accuracy. Near a secondary stope.

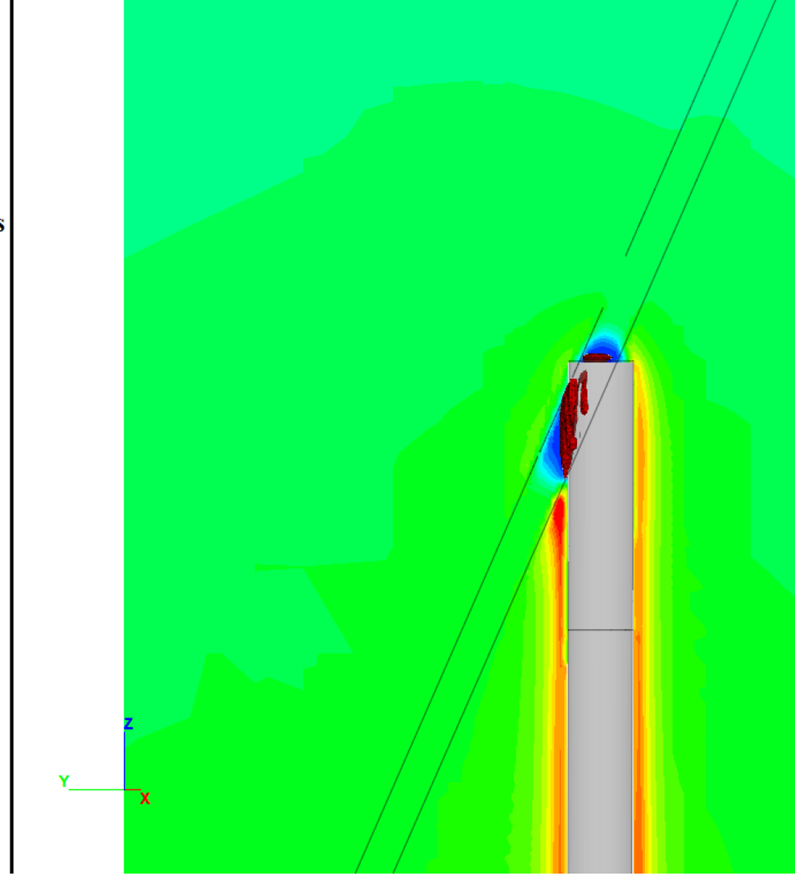

And this is an example of the stresses you get.

Example model using StopeX.